The characteristics of industrial liquid filter bag are introduced

Release time:

2022-11-25 11:14

【Abstract】:

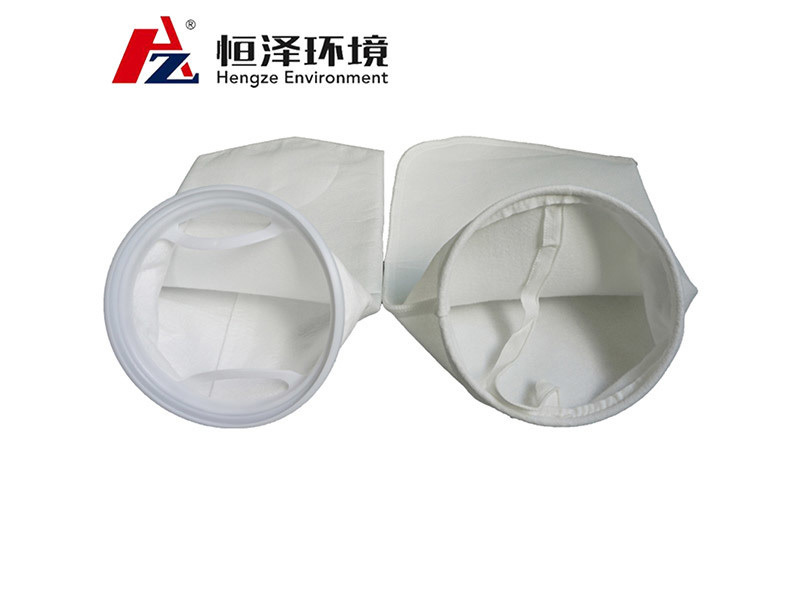

Industrial liquid filter bag commonly used materials are divided into polypropylene PP, polyester PET, ethylene nylon PE, nylon, etc.

Industrial liquid filter bag commonly used materials are divided into polypropylene PP, polyester PET, ethylene nylon PE, nylon, etc.

As a filter element, the filter bag is a key link in the filtration process, and the quality of the filter bag largely determines the filtering effect of users.

The filtrate filtration surface of the liquid filter bag is treated with special singling, which not only effectively prevents the fibers from getting out of the polluted filtrate, but also avoids the excessive plugging of the filter hole caused by traditional roller pressing treatment and shortening the life of the filter bag. All raw materials are white, without any special bleaching treatment, fully in line with environmental protection standards. Moreover, due to the three-dimensional filter layer of needled felt, when liquid flows through the filter bag, particles will remain on the inner surface and deep layer of the liquid filter bag due to the deep filtration mechanism, which has a high trapping efficiency for solid or colloidal particles. The uniform thickness of the needled felt, the stable opening rate and the full strength make the efficiency of the filter bag stable and the operation time longer. Five threads and two stitches are stitched closely to ensure that each liquid filter bag can achieve good filtration protection. A wide range of applications, suitable for various industries of liquid filtration.

Here are the advantages of industrial liquid filter bags:

1, industrial liquid filter bag even after the improvement of the stitching of the bag mouth, there is still no high protrusion, leading to the occurrence of lateral leakage.

2. Argon arc welding technology of stainless steel and galvanized steel ring. The diameter error is less than 0.5mm, and the horizontal error is less than 0.2mm. The filter bag made of this kind of steel ring can be installed in the equipment to improve the sealing degree and reduce the probability of side leakage.

3, the use of non-silicone oil cooling high-speed industrial sewing machine production, this production mode will not produce silicone oil pollution.

4, industrial liquid filter bag labeled with product specifications and models of the label selection is easy to replace, in order to prevent the filter bag in use of labels and ink caused by filtrate pollution.

5, industrial liquid filter bag filtration accuracy range from 0.5 to 300 microns. Its material is divided into polyester and polypropylene nylon, etc.

Liquid filter bag has a wide range of application scenarios, suitable for filtering general industrial liquid such as electroplating, E, D paint, ink, paint, food and other chemical liquid; Acid and alkali resistant fiber has high mechanical strength and can be used repeatedly.

More product information please contact 18988618180 (wechat same number)

Previous page

Next page

Previous page

Next page