The daily maintenance of the bag filter is divided into 8 steps

As a basic dust removal equipment, cloth bag dust collector needs to be treated seriously for its daily maintenance work, so as to prolong its service life, play the utility of dust removal and smoke removal for a longer time, and create value for enterprises.

How to use dust filter bags correctly

Bag type dust removal filter bag is often used in dust removal equipment of a kind of accessories, and such an accessory can be said to be an important part of the whole dust removal device, with such a device, dust removal equipment can better play their role.

The main cause of dust collector bag damage

The high velocity of bag dust collector is the main reason for the damage of bag dust collector. In recent years, some units blindly reduce equipment costs and increase profits. In the design of bag dust collector, the dust removal speed is increased. In a short time, the user has no obvious reaction, but the service life of the bag dust collector is greatly shortened. This not only saves money for customers, but also brings great financial burden and wastes time.

Classic application of dust removal cloth bag cement industry

Cement industry as an important industry, large-scale technical equipment to achieve not only to (in) building materials industry take the lead in implementation, but also in the green, low carbon development, purifying environment, and take the lead in the governance of atmospheric pollution standards. The introduction of ultra-low emission standards: soot emissions of less than 10 milligrams, enforcement is increasingly strict. This is also our material selection in filter material and made more improve production technology, etc. Hengze can now achieve ultra-low emissions of 10 mg or even 5 mg.

Selection and application of cloth bag dust collector

Under the background of general dust control in the country, environmental protection equipment such as dust collector is popular in the market. But in what kind of operating environment to choose what kind of precipitator products? In this paper, 7 main factors and 4 auxiliary factors, such as gas amount, dust dispersion and density, dust concentration, dust specific resistance and dust temperature, are explained in detail.

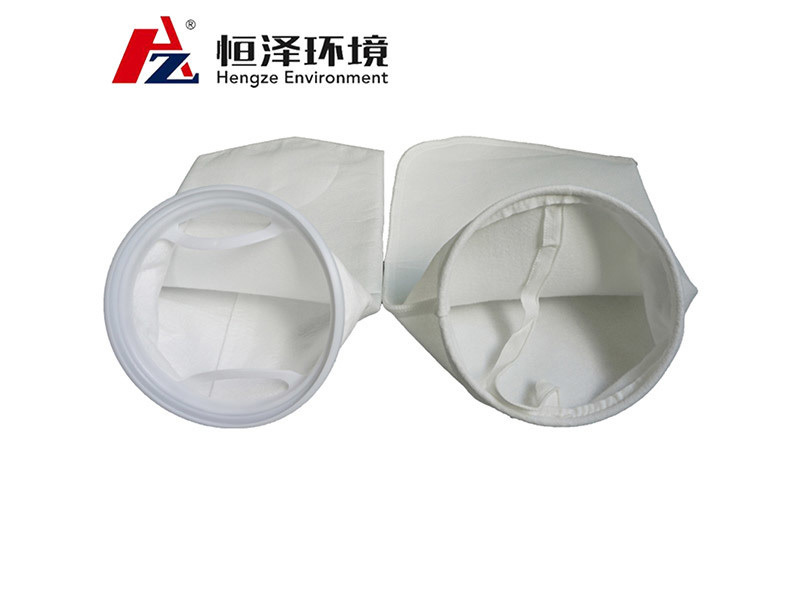

The characteristics of industrial liquid filter bag are introduced

Industrial liquid filter bag commonly used materials are divided into polypropylene PP, polyester PET, ethylene nylon PE, nylon, etc.

The dust bag should be installed as such

Dust removal bag is a consumption part of dust removal equipment, which needs to be replaced after 1-3 years of operation when it is blocked or damaged.

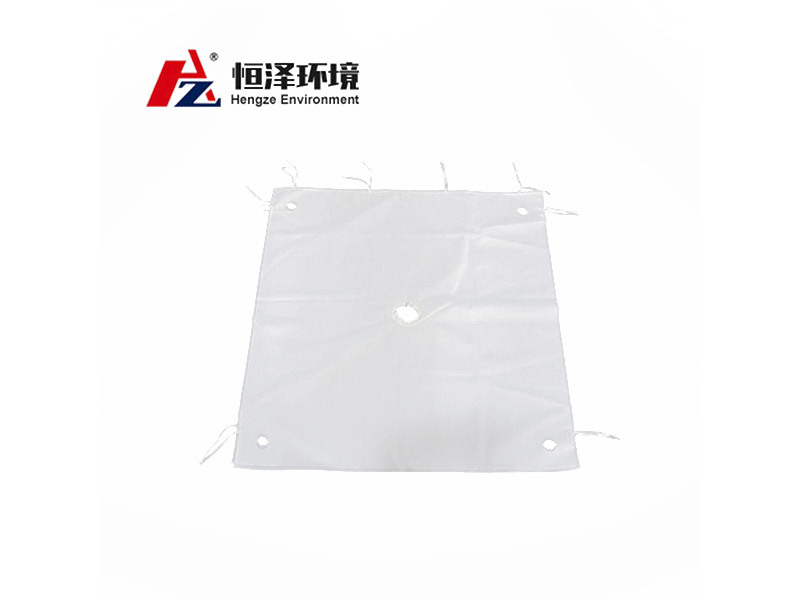

Filter press filter cloth type and performance introduction

Polyester staple fiber filter cloth material properties: acid resistance, alkali resistance. Good wear resistance, corrosion resistance, recovery, conductivity is very poor. Polyester fiber temperature resistance is generally 130- 150 degrees Celsius, the product has the advantages of ordinary felt filter cloth, but also very good wear resistance, has a high cost performance and become the use of felt filter material variety. Filtration performance: The raw material structure of polyester staple fiber filter cloth is short and hairy, and the woven fabric is dense, with good particle retention, but poor stripping and air permeability. Strength wear resistance, water leakage is also less than polyester long fiber filter cloth.

Bag filter air volume calculation

The average speed of the flue gas before entering the bag dust collector X the cross-sectional area of the dust collector inlet. It should be noted that the unit should be unified, generally cubic meters/hour.